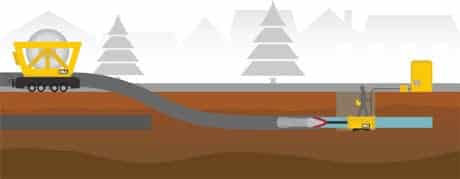

We use a portable winch to assist the pneumatic bursting process. The cracking hammer is used to break and replace the host pipe. The tools to burst the pipe are placed at either the front or rear end of the bursting hammer, to transfer the cracking energy into the host pipe. The expander then rearranges the burst pieces of the host pipe into the nearby soil and enlarges the hole that has been created so that a new pipe with either the same or a larger diameter can be pulled in.

A winch wire is firstly pulled into the host pipe via using a fibreglass rod. The newly created pipes are then combined outside the pit. The new pipe is attached to the hammer which is then connected to the air compressor and summoned into the host pipe with the winch.

The process of the pipe bursting begins with the compressor. The pulling force of the winch is what helps the forward movement and stability of the cracking hammers direction. With the arrival of the cracking hammer in the exit pit, it can then be removed or pulled back through the new pipe into the launch pit if space is confined.

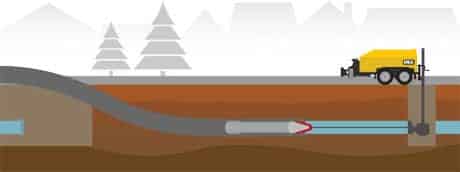

STATIC/HYDRAULIC Pipe Bursting

The hydraulically propelled pipe bursting rig is located strategically inside the exit pit. Having a flexible guiding rod allows for smooth installation of the bursting rods when going through the host pipe. Once at the launch pit, the guiding rod is then taken over by a bursting tool, expander and new pipe.

The hydraulic pipe bursting rig then motions back the entire arrangement through the host pipe towards the exit pit.